Anticorrosion tests >> Flash Rusting |

Flash rust: term used in the language of paint to describe the very rapid onset (flash) of rust on a metal substrate coated with an aqueous paint. This phenomenon occurs during the phases of application and drying. Our additives are used, among other properties, to prevent this oxidation. The aqueous coatings cause corrosion of support during their period of drying, upon application to a metal surface, this being due to the presence of water. The corrosion shows tasks on the film and can act on its cohesion and its adhesion to the substrate.

The Anti flash-rust additive inhibits corrosion during the drying period. It acts as the coating contains water. This test evaluates the effectiveness of the antiflash rust additive in the coating where it will be used. The test duration varies depending on the coating to be tested. The results are expressed as degree of corrosion.

Steps :

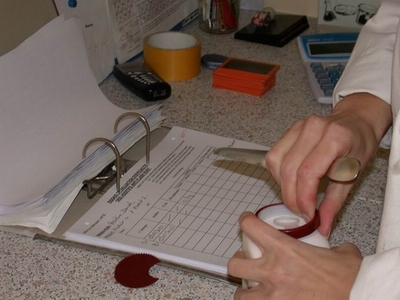

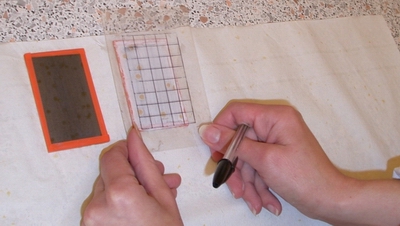

Sample preparation |

|

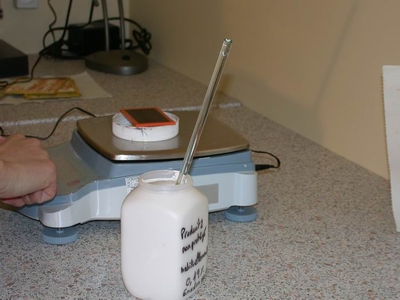

Zeroing tare |

|

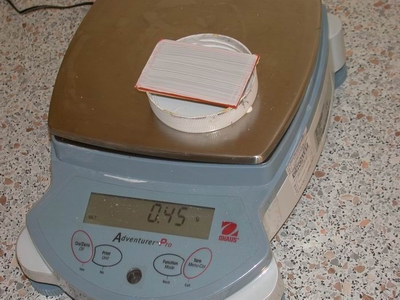

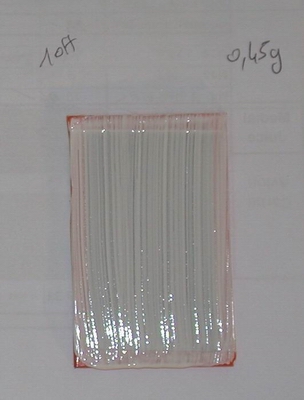

Application of paint 0.45g |

|

Weight verification |

|

Flash rust, time zero |

|

Modified atmosphere saturated with moisture |

|

Flash Rust after 20 minutes in an atmosphere saturated with moisture |

|

Scoring rust |